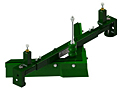

Keep rocks, fines, clumps and other debris off your belt and away from your tail pulley with the Argonics Aluminum V-Plow. This plow is equipped with our best Kryptane® urethane side blades and an angled front nose plow.

The Aluminum plow is designed for systems that need protection but at an affordable price. It clears debris while floating on the belt and will self-adjust as it wears.

The Aluminum V-Plow is designed to be lightweight yet durable, with a .375” (9.5 mm) thick, 2” x 2” (50.8 mm x 50.8 mm) aluminum angle iron frame.

Benefits:

• Equipped with Kryptane® G83 polyurethane blades that are easily replaceable and provide 3” (76 mm) of wear before needing service

• No hoses, cables, shocks or mud-packed components to deal with

• Aluminum V-Plow comes disassembled in a box, allowing for reduced shipping costs

• Wear travel limit mounting brackets

• Comes standard with safety chains

/Asset/Argonics Aluminum V Plow.jpg

/Asset/Argonics Eraser MDP.jpg

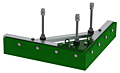

Belt Wipers are designed to provide solutions for cleaning belts in environments from wet clay to frozen coal.

Benefits:

• 60% less coefficient of friction than rubber

• Reduces drag on motor horse power used

• Available in 4", 5", 6", 8", 9", 10" & 12" widths

• Field tested with 8-10 times the wear life over quality rubber wipers

• Longer life wipers translates into lower maintenance and labor savings

• No more scraps, scrapers are sold by the inch so you only order what you need

• Nonporous, will not collect fines or other materials that can damage your belt

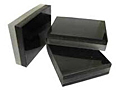

KS02 - Double Durometer BeltWiper

Utilizing an exclusive process, the two layers of the KS02 are chemically bonded, and will not

separate in the harshest of environments. The harder durometer 93A scrapes the conveyor

belt clean in rugged applications, while the softer durometer 70A produces a squeegee effect,

removing water and giving the wiper more flexibility. KS02 is available in thicknesses ranging

from 3/4” to 2”.

KS03 - Triple Durometer SuperWiper

Utilizing three chemically bonded layers, the KS03 is designed for use in environments where

a harder polyurethane surface is needed. The KS03 has a softer 70A durometer sandwiched

between two hard 93A durometer pieces of polyurethane. This provides an extremely tough

scraping surface, yet maintains flexibility. This unique design also allows you to turn the

wiper around when worn, giving you the longest wear life of any belt scraper on the market.

KS03 is available in thicknesses ranging from 1” to 2”.

KS04 - Ceramic BeadWinterWiper

Ceramic wear beads are embedded into the polyurethane of the KS04, giving you absolutely

the toughest wiper available on the market today. This design will break apart any buildup in

frozen environments where plastics and rubber fail to do the job. KS04 is only available in

thicknesses of 1/2”, 3/4” and 1”.

Technical Specifications:

• FDA Food Grade & MSHA Accepted

• Exclusive Profile reduces your yearly belt cleaning costs

• Super-effective cleaning at an affordable price

• Non-destructive design extends the life of all conveyor components

• Design allows greater full-blade contact, while easily deflecting belt splices

• No adaptation necessary - direct retrofit

• Removes excessive carryback while reducing belt wear

• Reduces clean-up costs and creates a cleaner, safer work environment.

• High performance, long wearing Kryptane Polyurethane

• Heavy duty extruded aluminum insert

• Several formulations are available to fit your specific applications

• Single pin - no tool fast blade change

Argonics replacement blades can be used with the following belt cleaners:

ARCH Environmental Equipment, Inc.

Gordon Saber® Mini Blade (Raptor MGS™)

Gordon Saber® Primary Blade (Raptor GS™)

Gordon “SCM” Channel Mount Blade (Raptor GSC™)

Gordon NU System Blade (Raptor GNU™)

ASGCO Manufacturing, Inc.

Mini-Skalper (Raptor AGM™)

Skalper I® Blade (Raptor AGC™)

Skalper II®

Skalper IV® Blade (Raptor AG2™)

Classic Conveyor Components Corporation

Head Shed™ MD Primary Belt Cleaner (Raptor CMS™)

Head Shed™ HD Primary Belt Cleaner (AccuFlo CHS™)

J&H Equipment

BeltMaster™ Primary Belt Cleaner (Raptor JHB™)

Martin Engineering

QC® #1 Low Profile Single Notch Blade (Raptor MLP™)

QC® #1 Low Profile Double Notch Blade (Raptor MDL™)

QC® #1 Standard Profile Single Notch Blade (Raptor MSP™)

QC® #1 Standard Profile Double Notch Blade (Raptor MDS™)

QC® #1 Heavy Duty Profile Blade (Raptor MHP™)

QC® #1 Extra Heavy Duty Profile Blade (Raptor MXA™)

QC® #1 Extra Heavy Duty Profile Blade (Raptor MXB™)

Pit Viper™ Blade (Raptor MPV™)

Durt Tracker® Blade (Raptor MHD™)

Durt Tracker® Blade (Raptor DT2™)

XHD Durt Tracker® (Raptor MEX™)

SAF-2™ Blade (AccuFlo SF™)

Durt Tracker® HD Reversing Blade (AccuFlo MET/ME/MEU™)

Durt Hawg® Primary Blade (Raptor MDH™)

Durt Hawg® Primary Blade (Raptor DH2™)

Durt Hawg® Secondary Blade (AccuFlo PigHead™)

QC® #2 Secondary Blade (AccuFlo TQ2™)

Richwood Industries Inc.

Combi-T® 1C Blade (Edge-Z™)

Scorpio

Scorpio Secondary Blade (AccuFlo SCS™)

Svedala

Trellex Primary Blade (Raptor TPC™)

The Super-G’s unique “pass-through” mainframe design allows material to freely fall through it, keeping your systems online with little to no maintenance. This system is based on the same heavy duty mainframe and Perma-Torque tensioner as our Eraser system. The urethane cartridge holds the 6” tungsten-tipped blades, which allows the blades to flex with and maintain contact and pressure against the belt.

Benefits:

• Effective performance for wet, sticky secondary cleaning applications

• Solid urethane cleaning blades also available

• The Perma-Torque™ internal central tensioner is adjustable from 20 to 80 ft-lb (27 to 108 Nm) resulting in uniform cleaning pressure to the conveyor belt

• Compact mounting footprint only protrudes 5” (127 mm) from mounting structure

• Brightly colored safety yellow end caps seal the Safe Torque™ ratchet from dust and water contamination

• Single pin blade attachment means quick and simple blade change out

Recommended Belt Speeds:

• Urethane Blade: 0 – 500 fpm (2.54 m/s)

• Tungsten Blade: 0 – 1000 fpm (5.08 m/s)

Mounting Distance:

• Vertical: 7.5” ± .25 (190 mm ± 6)

• Horizontal: up to 16” (406 mm)

Mounting Distance:

• Vertical: 1” (25 mm) min. and 4” (102 mm) max.

• Horizontal: up to 16” (406 mm)

The XTC with a tungsten carbide blade is one powerful reversing conveyor cleaner. The system can handle wet, dry, sticky or slimy conditions. The unique Web Torque™ tensioner has enough give for mechanical splices and the flow-over blade design reduces material build-up. The XTC is designed with the same toughness and durability as our standard Eraser, with a .25” (6 mm) thick, 3” x 3” (76 mm x 76 mm) tube stock steel mainframe and heavy duty stub ends.

Benefits:

• Tungsten carbide blade is ideal for high-speed belts

• Specifically designed for reversing conveyor belt applications

• The Web Torque™ shock absorbs the high level of impact and contortion which are present in most reversing applications

• No rusty springs, hoses, cables, shocks or mud-packed components to deal with

Recommended Belt Speeds:

• Tungsten blade: 0 – 1000 fpm (5.08 m/s)

Mounting Distance:

• Vertical: 14.62” ± .25 (371 mm ± 6)

• Horizontal: up to 16” (406 mm)