5314 Palmero Court

Buford, GA 30518

Ph:800-875-0280

Website: www.jamiesonequipment.com

The modular TX Tubular Screw Conveyor system is highly versatile. TX Screw Conveyors are manufactured in stainless steel with a suitable surface finishing grade appropriate for the application. Manufacture of the fabricated components is carried out on machines that guarantee a perfectly smooth surface due to which material residue is reduced to the minimum. TX Tubular Screw Conveyors are made up from a tubular trough that is equipped with at least one inlet and outlet spout, an end plate at each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with adjustable shaft sealing unit, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, TX Tubular Screw Conveyors are equipped with a gear motor that is suitable for the application. Depending on the material to be handled TX Tubular Screw Conveyors come in a light or medium-heavy-duty design.TX Screw Conveyors are available with ATEX, zone 22 certification.

Performance and Technical Features:

• Standard design in 304 L or 316 L stainless steelPolygonal or cylindrical inlet and outlet spouts according to WAM® standard

• End bearing assemblies with externally adjustable shaft seals (stuffing box, air or gas-purged, others)

• Wide range of intermediate hanger bearings appropriate for the application (also self-lubricating)

• End flanges welded orthogonally on the trough on special jigs

• End plates carrying flanged end bearing assemblies and closing off the trough

• Modular length helicoid screw flighting with square or variable pitch welded on centre pipe with shaft coupling each end

• Screw sections connected by splined or bolted shaft couplings

• Screws accurately balanced

• Bearing assemblies entirely designed by WAM® to offer the right product for each application

• WAM® drive units with integrated end bearing assembly and adjustable shaft sealing unit (screws run perfectly balanced due to drive unit directly mounted on screw pipe; substitutes coupling or chain transmission with special drive mount)

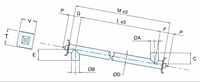

Item # |

A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

F (mm) |

G (mm) |

L (mm) |

M (mm) |

P (mm) |

T (mm) |

V (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TX100 | N/A 114 | N/A 114 | N/A See inlet/outlet spouts | N/A 114 | N/A See inlet/outlet spouts | N/A 140 | N/A 120 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 114 | N/A 280 | N/A 265 |

| TX120 | N/A 139 | N/A 139 | N/A See inlet/outlet spouts | N/A 139 | N/A See inlet/outlet spouts | N/A 140 | N/A 120 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 114 | N/A 280 | N/A 265 |

| TX150 | N/A 168 | N/A 168 | N/A See inlet/outlet spouts | N/A 168 | N/A See inlet/outlet spouts | N/A 160 | N/A 140 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 124 | N/A 280 | N/A 265 |

| TX200 | N/A 219 | N/A 219 | N/A See inlet/outlet spouts | N/A 219 | N/A See inlet/outlet spouts | N/A 180 | N/A 160 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 124 | N/A 355 | N/A 315 |

| TX250 | N/A 273 | N/A 273 | N/A See inlet/outlet spouts | N/A 273 | N/A See inlet/outlet spouts | N/A 220 | N/A 180 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 124 | N/A 410 | N/A 365 |

| TX300 | N/A 323 | N/A 323 | N/A See inlet/outlet spouts | N/A 323 | N/A See inlet/outlet spouts | N/A 220 | N/A 220 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 124 | N/A 465 | N/A 435 |

| TX350 | N/A 406 | N/A 406 | N/A See inlet/outlet spouts | N/A 406 | N/A See inlet/outlet spouts | N/A 270 | N/A 280 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 151 | N/A 535 | N/A 485 |

| TX400 | N/A 457 | N/A 457 | N/A See inlet/outlet spouts | N/A 457 | N/A See inlet/outlet spouts | N/A 280 | N/A 320 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 151 | N/A 590 | N/A 540 |

| TX500 | N/A 558 | N/A 558 | N/A See inlet/outlet spouts | N/A 558 | N/A See inlet/outlet spouts | N/A 340 | N/A 360 | N/A Rounded up to 10 mm | N/A L+F+G | N/A 162 | N/A 740 | N/A 655 |