5314 Palmero Court

Buford, GA 30518

Ph:800-875-0280

Website: www.jamiesonequipment.com

Global Air Blasters are blast aerators consisting of a compressed air reservoir with a quick opening valve that releases the stored air in a sudden, high-energy blast. This blast is directed through a discharge pipe to aerate and dislodge material, and restore flow. In a direct blast Air Blaster the air in the reservoir or tank passes directly into the discharge pipe without bends or obstructions in the air course that impede the flow of air. This is important because the quicker the air discharges, the greater the velocity and force of the blast and, therefore, the greater the amount of material affected.When used in combination, multiple Air Blasters can restore flow to hundreds, thousands, or millions of cubic feet of material. Air Blasters are activated manually or by a micro-controller based sequencing timer that controls the firing time interval and sequence of one or more Air Blasters.

Air Blasters are an easy way to solve bulk flow problems in silos, hoppers, chutes, and storage piles. Use Air Blasters where vibration is not practical, other methods are too expensive, dangerous or destructive, or nothing else works. They are commonly used when it is not practical to physically shake stuck material loose. For instance, large concrete bunkers and storage piles on the ground are impossible to vibrate, but are common locations of bulk material flow problems.

Air Blasters are recommended for a wide range of material clogs and jams, in hoppers of any size, and are well suited for large structures of any type. They are effective for very cohesive, difficult materials. For instance, wood chips are very difficult to dislodge by other means, but respond very well to the quick-release Air Blaster.

| Items |

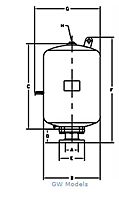

GW2.5-8-24 GW Series Standard Air Blasters |

GW4-12-28 GW Series Standard Air Blasters |

GW-4-20-30 GW Series Standard Air Blasters |

GW6-24-48 GW Series Standard Air Blasters |

GW6-30-60 GW Series Air Blasters |

|||||

| (A) Inch | N/A 2.5 | N/A 4.0 | N/A 4.0 | N/A 6.0 | N/A 6.0 | |||||

| (B) Inch | N/A 8 | N/A 12 | N/A 20 | N/A 24 | N/A 30 | |||||

| (C) Inch | N/A 24 | N/A 28 | N/A 30 | N/A 48 | N/A 60 | |||||

| (D) Inch | N/A 4.5 | N/A 4.6 | N/A 4.6 | N/A 6.0 | N/A 6.0 | |||||

| (E) Inch | N/A 7 | N/A 9 | N/A 9 | N/A 11 | N/A 11 | |||||

| (F) Inch | N/A 31.2 | N/A 35.3 | N/A 37.3 | N/A 56.7 | N/A 68.7 | |||||

| (G) Inch | N/A 9.5 | N/A 13.5 | N/A 21.5 | N/A 25.6 | N/A 31.5 | |||||

| Tank Volume | N/A 0.7 cu ft (19 L) | N/A 1.7 cu ft (49 L) | N/A 5.0 cu ft (142 L) | N/A 10.6 cu ft (299 L) | N/A 22.8 cu ft (645 L) | |||||

| Fill Time (Sec) at 70 psi | N/A <10 | N/A 15 | N/A 35 | N/A 90 | N/A 210 | |||||

| Shot Time (sec) at 70 psi | N/A 0.08 | N/A 0.08 | N/A 0.18 | N/A 0.20 | N/A 0.38 | |||||

| Force (lbs) at 70 psi | N/A 244 | N/A 244 | N/A 1075 | N/A 2681 | N/A 3190 | |||||

| Fill Time (sec) at 80 psi | N/A <10 | N/A 15 | N/A 40 | N/A 90 | N/A 210 | |||||

| Shot Time (sec) at 80 psi | N/A 0.09 | N/A 0.08 | N/A 0.20 | N/A 0.21 | N/A 0.40 | |||||

| Force (lbs) at 80 psi | N/A 275 | N/A 1021 | N/A 1350 | N/A 2812 | N/A 3345 | |||||

| Fill Time (sec) at 90 psi | N/A <10 | N/A 15 | N/A 40 | N/A 90 | N/A 210 | |||||

| Shot Time (sec) at 90 psi | N/A 0.09 | N/A 0.08 | N/A 0.21 | N/A 0.22 | N/A 0.42 | |||||

| Force (lbs) at 90 psi | N/A 288 | N/A 1200 | N/A 1485 | N/A 3230 | N/A 3840 | |||||

| Fill Time (sec) at 100 psi | N/A <10 | N/A 15 | N/A 40 | N/A 105 | N/A 210 | |||||

| Shot Time (sec) at 100 psi | N/A 0.09 | N/A 0.08 | N/A 0.22 | N/A 0.23 | N/A 0.44 | |||||

| Force (lbs) at 100 psi | N/A 330 | N/A 1300 | N/A 1635 | N/A 3333 | N/A 3965 | |||||

| Manufacturer | N/A Global | |||||||||

|

|

||||||||||