5314 Palmero Court

Buford, GA 30518

Ph:800-875-0280

Website: www.jamiesonequipment.com

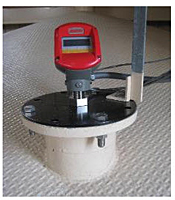

The BinMaster 3DLevelScanner uses non-contact, dust-penetrating technology to provide unsurpassed bin volume accuracy. Unlike single point devices, it works by measuring multiple points within the bin accounting for irregular material topography. This advanced acoustics-based technology is proven to perform in powders and bulk solids contained in tanks, silos, warehouses, as well as open bins and piles. It is ideal for food processing, pharmaceuticals, or chemicals where contact with the material being measured must be avoided. Its unique 3D mapping capabilities provide a visual representation of bin contents, detecting cone up or down as well as sidewall buildup.

BinMaster was first to the North American market with 3DLevelScanner technology. Since March of 2009, BinMaster has installed hundreds of 3DLevelScanners across the continent in diverse applications including the grain, bioenergy, cement, aggregates, wood, power and plastics markets.

BinMaster is the only company in the US with an in-house dedicated 3D sales and technical staff vastly experienced in specifying, installing and servicing this advanced technology. When it comes to 3D technology, no other company in North America has more expertise than BinMaster.

Features:

• Continuous and non-contact measurement

• Measures uneven powder or solid material surfaces

• Detects cone up, cone down and sidewall buildup

• Provides minimum, maximum and average distances

• Performs in extreme levels of dust

• Calculates highly accurate bin volume

• Communications include 4-20/HART, Modbus RTU, TCP/IP and RS-485

• Measuring range up to 200 feet

• Self-cleaning with minimal maintenance

Specifications:

• Preferred Applications: Powders and solids

• Measuring Range: 200 feet (61 meters)

• Process Temperatures: -40°to +185°F (-40°to +85°C) Standard

• Process Pressure: -0.2 – 3 bar (-2.9 to 14.5 psi)

• Signal Output: 4-wire 4 - 20 mA/HART/RS-485/Modbus

• Emitting Frequency: 3 KHz to 10 KHz

• Supply Voltage: 20 to 32 VDC

• Power Consumption: Max 1.5 W at 24 VDC

• Hazardous Locations: CFM Intrinsically Safe Class I, II, Division I, Groups C, D, E, F, G (US & Canada)

Applications:

• Suitable for pellets, granulars, powders and most other bulk solids

• Bin, tanks and silos where the material surface has uneven topography

• Grain, seed, feed and food processing

• Ethanol, bioenergy and power plants

• Aggregates and cement

• Mining and metals

• Chemical processing and plastics manufacturing

• Pulp, paper & wood pellets

Item # |

Measuring Range |

Process Fitting |

Signal Output |

Weight |

Power Consumption |

Bin Height |

Bin Diameter |

Beam Angle |

|---|---|---|---|---|---|---|---|---|

| 730-0559 | N/A 200 Feet (61 meters) | N/A Thread, Flange | N/A 4-wire 4-20mA/HART/RS-485/Modbus | N/A 2.6 KHz to 7 KHz | N/A Max 4 VA; at 2.1 W | N/A Up to 200' tall | N/A Up 2 14' | N/A 30° |

| 730-0560 | N/A 200 Feet (61 meters) | N/A Thread, Flange | N/A 4-wire 4-20mA/HART/RS-485/Modbus | N/A 21.8 lbs- 25.1 lbs | N/A Max 4 VA; at 2.1 W | N/A Up to 200' tall | N/A Up to 45' | N/A 70° |

| 730-0561 | N/A 200 Feet (61 meters) | N/A Thread, Flange | N/A 4-wire 4-20mA/HART/RS-485/Modbus | N/A 21.8 lbs- 25.1 lbs | N/A Max 4 VA; at 2.1 W | N/A Up to 200' tall | N/A Up to 45' | N/A 70° |