Jamieson Equipment Co

5314 Palmero Court

Buford, GA 30518

Ph:800-875-0280

Website: www.jamiesonequipment.com

5314 Palmero Court

Buford, GA 30518

Ph:800-875-0280

Website: www.jamiesonequipment.com

| Items |

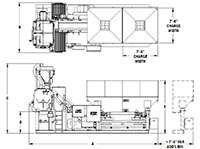

16 / 21 24 Feet (ft) 9 Inch (in) Overall Length (A) One-Piece Skid Mounted Batch Plant |

30 27 Feet (ft) 1 Inch (in) Overall Length (A) One-Piece Skid Mounted Batch Plant |

54 29 Feet (ft) 7 Inch (in) Overall Length (A) One-Piece Skid Mounted Batch Plant |

|||

| Description | N/A Quick & Easy Installation - Pre-Plumbed, Pre-Wired & Shop Tested | |||||

| Brands | N/A Mix® | |||||

| Overall Length (A) | N/A 24 ft 9 in. | N/A 27 ft 1 in. | N/A 29 ft 7 in. | |||

| Overall Width (B) | N/A 9 ft 6 in. | N/A 10 ft 9 in. | N/A 11 ft 10 in. | |||

| Overall Height (C) | N/A 13 ft 4 in. | N/A 14 ft 3 in. | N/A 16 ft 5 in. | |||

| Discharge Height (D) | N/A 4 ft | N/A 4 ft | N/A 5 ft | |||

| 5 Ton Bin Discharge Height ( E) | N/A 7 ft 10 in. | |||||

| 10 Ton Bin Discharge Height ( E) | N/A 9 ft 7 in. | |||||

| 15 Ton Bin Discharge Height ( E) | N/A 11 ft 4 in. | |||||

| Mixer Stand and Cleanout Platform |

N/A

1/2 thru 2 Yard Mixers Horizontal Mixer - Platform with handrails, toe boards and ladder 3’ wide walkway on one side with 4’ high stand Turbin & Planetary Mixer - Platform with handrails, toe boards and ladder 3’ wide walkway on three sides with 4’ high stand |

|||||

| Aggregate Storage Bins |

N/A

Two or three bin (10, 15 or 20 tons each) assembly Mounted on a single frame w/ load cells Pneumatically operated double clamshell discharge gate and adjustable gate stop Single solenoid valve and air vibrator |

|||||

| Skid Mounted and Pre-Wired |

N/A

Skid assembled plant for ease of installation Completely wired and plumbed for operation Multi-motor starter panel Shop tested |

|||||

| Cement Weigh Batcher |

N/A

Batcher split into one or two equal compartments Pneumatically operated butterfly discharge valve Single solenoid valve, limit switch, and air vibrator |

|||||

| Water Meter |

N/A

Water system complete with water meter Butterfly shut-off valve with solenoid valve |

|||||

| Aggregate Belt Conveyor |

N/A

Belt conveyor complete with 230/460 volt electric drive motor "Emergency Stop" pull-cord |

|||||

| Model E-150 Batch Control |

N/A

Fully automatic sequential batching of materials Control utilizes micro computer Scales for cements and aggregates Recordation program for materials use Remote access for service trouble-shooting |

|||||

| Note | N/A Made in U.S.A | |||||

|

|

||||||