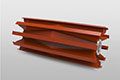

Mine Duty Extreme™ Wing Pulley

Benefits:

• Maximum life, longer wear

• Helps protect bottom belt cover from cuts and tears

• Less vibration

• Smoother belt contact

• Less metal fatigue

• Improved self cleaning

• Exclusive 1-1/2” diameter round bar wing tips wear 2-1/2 times longer and prevent possibility of belt cover cuts and fabric ply separation caused by flat, square and quarter round tips

• Minimum 1/2” wing thickness and “Never Fold” Wing Support Rings™ prevent wing and pulley failure

• Increased gusset angle improves self cleaning action resulting in a cleaner running belt with less chance of belt damage

Construction:

• 1-1/2” diameter solid steel round face bar

• 1/2” thick wings

• 1/4” gussets

Options:

• Hot Vulcanized Wing Pulley Lagging

• Stainless steel construction available

• “AR” abrasion resistant wing tips available

• Optional Douglas Keyless Locking Assemblies available

• Shafting

• Bearing Assemblies

• Take-Up Systems

/Asset/Mine Duty Extreme™ Wing Pulley.png

Mine Duty/Mill Duty Wing Self Cleaning Conveyor Pulleys

Benefits:

• Douglas Mine Duty/Mill Duty Wing Style Pulleys feature exclusive minimum 1" solid steel round bars

• Increases service life

• Helps prevent wing folding damage

• Wears up to three times as long as other manufacturer’s formed flat bar or 1/4 moon bar

• Protect belt bottom cover from cuts and tears

• Less belt vibration from smoother belt contact

• Special self-cleaning angle formed by gussets discharges material away from the belt and the pulley face helping to prevent material build up

• Unique design creates a refined motion that helps to dislodge materials from the belt top cover

Construction:

• Heavy construction of the wings and gussets reduces the likelihood of metal fatigue and pulley failure in severe applications

• Crown face pulleys are furnished standard, flat face must be specified

• Douglas hubs and bushings are interchangeable with QD® or XT® style

Options:

• Hot Vulcanized Wing Pulley Lagging

• Stainless steel construction available

• “AR” abrasion resistant wing tips available

• Optional Douglas Keyless Locking Assemblies available

• Stabilizing Rings

• Shafting

• Bearing Assemblies

• Take-Up Systems

Quarry Duty Wing Self-Cleaning Pulleys

Benefits:

• Douglas Quarry Duty Wing Style Pulleys feature exclusive minimum 1” solid steel round bars:

– Increases service life

– Helps prevent wing folding damage

– Wears three times as long as other manufacturers’ formed flat bar or 1/4 round bar

– Protect belt bottom cover from cuts and tears

– Less belt vibration from smoother belt contact

• Special self-cleaning angle formed by gussets discharges material away from the belt and the pulley face helping to prevent material build up

• Unique design creates a refined motion that helps to dislodge materials from the belt top cover

• Round bar increases belt fastener life

Construction:

• Heavy construction of the wings and gussets reduces the likelihood of metal fatigue and pulley failure in severe applications

• Crown face pulleys are furnished standard, flat face must be specified

• Douglas hubs and bushings are interchangeable with QD®, XT®, HE or Taper Lock

• 1” - 2” thick round bars

Options:

• Wing Support Rings

• Hot Vulcanized Wing Pulley Lagging

• Stainless Steel

• “AR” abrasion resistant wing tips available

• Optional Douglas Keyless Locking Assemblies available

• Shafting

• Bearing Assemblies

• Take-Up Systems

Standard Heavy Duty Wing Self-Cleaning Pulleys

Benefits:

• Meets or exceeds CEMA/ANSI specifications

• Douglas Heavy Duty Wing Style Pulleys feature exclusive minimum 3/4" solid steel round bars Increases service life

• Helps prevent wing folding damage

• Wears twice as long as other manufacturers’ formed flat bar or 1/4 half moon bar

• Protects belt bottom cover from cuts and tears

• Less belt vibration from smoother belt contact

• Special self-cleaning angle formed by gussets discharges material away from the belt and the pulley face helping to prevent material build up and belt damage from conveyed material

• Unique design creates a refined motion that helps to dislodge materials from the belt top cover

Construction:

• Crown face pulleys are furnished standard, flat face must be specified

• For approximate shipping weights please consult JEC

• Douglas hubs and bushings are interchangeable with QD® and XT® style

Options:

• Hot Vulcanized Pulley Lagging

• Shafting

• Bearing Assemblies

• Take-Up Systems

• Stainless steel construction available

• Optional Douglas Keyless

• Locking Assemblies available

• Stabilizing Rings

Wing Pulleys

Features:

• From light, portable applications to high tonnage, extreme jobs

• CEMA, Mine 1.5, Mine 2.0, super and engineered classes

• Specialty: Spiral drums and wings, deflection wheels and dead shaft conveyor pulleys

Performance Matched Design

• Complete assembly from Superior including bearings, couplings, gearing, etc.

• Engineers apply Finite (FEA) to build per application stress conditions

Quality Craftsmanship

• Robotic welding machines for consistent, quality welds

• Hand welders trained and certified by (AWS)

Standard Size (custom sizes available on request):

• Diameters: Up to 60"

• Face Widths: Up to 120"

• Shafting: Up to 15"