Styling, strength, compactness, and simplicity of design have been combined to produce the Bray Series 92 direct acting and the Series 93 spring return pneumatic actuators.

Engineering excellence and precision manufacturing has produced a modular product line with reduced overall size requirements and economic savings. In addition all Bray accessories are fully modular and directly mount to the actuator – providing flexibility and efficiency at reduced cost.

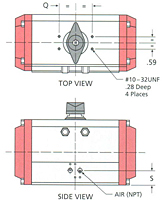

Bray Series 92/93 actuators are rack and pinion, opposed-piston actuators available in two versions: double acting for rotation of 90°, 135° and 180°, and spring return for 90° rotation.

The Series 92/93 actuators were designed primarily for pneumatic operation up to a maximum pressure of 140 psig (10 Bar) and for temperature ranges of -4°F to 200°F (-20°C to 93°C). For higher and lower temperature applications, consult Jamieson Equipment Company.

All double acting and spring return units are suitable for both on/off and throttling applications. Actuators which can be actuated with other media such as hydraulic oil or water are also available as an option.

The Series 92/93 is completely enclosed and self contained. The many features minimize maintenance and provide safe, simple disassembly and assembly.

Specifications:

• Torque: to 44,130 Lb-in (4,986 Nm)

• Pressure Rating: Max Pressure: 140psig (10 Bar)

• Temperature Range: Standard: -4°F to 200°F (-20°C - 93°C)

• Low: -40°F to 176°F (-40°C - 80°C)

• High: 0°F to 300°F (-18°C - 149°C)

• Body Materials: Extruded Aluminum Alloy, Anodized 316 Stainless Steel, Electroless Nickel Plated Body Exterior, Hard Anodized Body Exterior

• Output Shaft/Pinion: Carbon Steel, Zinc Plated, Stainless Steel

General:

• The actuator shall be pneumatically operated and must travel a minimum of 95º in each direction to allow for over travel adjustment.

• The actuator shall be rack and pinion design and the output torque shall be linear throughout travel.

• The actuator shall be totally enclosed in a single enclosure with no external moving parts.

• The actuator shall be factory lubricated with no field lubrication required.

• The actuator shall be able to mount in any position without loss of performance.

• All actuators (double acting or spring return) shall be suitable for both on-off and throttling applications.

Housing and End Caps:

• Housing design must have smooth lines to provide for self-drain capability.

• Housing shall be extruded, anodized aluminum alloy and all external fasteners shall be zinc plated carbon steel.

• All pneumatic passageways must be integral to the actuator housing to eliminate the need for external tubing.

• End caps shall be die cast aluminum alloy with corrosion resistant polyester coating.

• All seals shall be Buna-N and bearings shall be manufactured out of lubricated acetal resin.

Pistons:

• Shall be die cast aluminum alloy.

• Shall be provided with acetal piston guides and rings to extend the life of the actuator and reduce friction.

Output Shaft and Pinion:

• Must be manufactured out of hardened alloy steel and zinc plated for corrosion protection.

• Shall be a one piece design.

• The output shaft shall be provided with a mechanical, high visibility position indicator.

Travel Stops:

• The actuator must be supplied with two independent travel stop adjustments (one on each end of travel)

• Each end of travel (0º and 90º) shall have a minimum of +5º to -5º adjustment.

Spring Return System:

• Must be installed in the same housing as the double acting actuator with no additional housing extensions.

• Must be furnished as a self-contained spring cartridge system to assure safe disassembly of the actuator.

• Springs shall be coated spring steel for corrosion protection.

Service Requirements:

• Actuators shall be designed for pneumatic operation for the following service conditions:

• Pressure up to a maximum of 140 psig

• Available temperature ranges of -40°F (-40°C) to 300°F (149°C)

• Filtered air is recommended but not required.

• Optional units shall be available to operate with hydraulic oil or water if specified.

Testing:

• All actuators shall be factory tested to ensure proper operation.

Mounting:

• All actuators shall mount directly to the valve mounting flange and stem without the need for any brackets or couplings

Approvals & Certifications:

• SIL Certification

• ABS Certification

• Bureau Veritas Certification

Item # |

Item Name |

|---|---|

| 92-0630-11300-532 /Asset/Bray Series 92 Pneumatic Actuator.png | N/A Series 92 Double Acting Pneumatic Actuator (for 2" Butterfly Valves) |

| 92-0830-11300-532 /Asset/Bray Series 92 Pneumatic Actuator.png | N/A Series 92 Double Acting Pneumatic Actuator (for 3" Butterfly Valves) |

| 92-0930-11300-532 /Asset/Bray Series 92 Pneumatic Actuator.png | N/A Series 92 Double Acting Pneumatic Actuator (for 4", 5" and 6" Butterfly Valves) |

| 92-1190-11300-532 /Asset/Bray Series 92 Pneumatic Actuator.png | N/A Series 92 Double Acting Pneumatic Actuator (for 8" and 10" Butterfly Valves) |

| 92-1280-11300-532 /Asset/Bray Series 92 Pneumatic Actuator.png | N/A Series 92 Double Acting Pneumatic Actuator (for 12" Butterfly Valves) |

| 92-1600-11300-532 /Asset/Bray Series 92 Pneumatic Actuator.png | N/A Series 92 Double Acting Pneumatic Actuator (for 14" or 16" Butterfly Valves) |